FAQ's

Frequently Asked Questions

Is the project just an idea, or is it really going to happen?

Iverson e-Fuels is committed to turning the project into reality and a competent project team has been established to complete the project according to the project plan.

Who will purchase the green ammonia from Iverson eFuels?

There is a strong momentum driving the decarbonization of hard-to-abate sectors that are responsible for significant carbon emissions and that are difficult to electrify directly. Green ammonia plays an important role in this transformation. Green ammonia, for example, can be used as fuel for ships, contributing to the emissions reduction of large vessels that operate over longer distances. We want to contribute to substantial emissions reductions within the Norwegian shipping fleet and are in close dialogue with shipowners and the maritime supply industry. In addition, apart from its use as ship fuel, ammonia can be used in the chemical industry and the agricultural sector.

What is the expected timeline for the project?

Production of green ammonia is expected to commence in 2029.

How is green ammonia produced?

Green ammonia is synthesized by combining green hydrogen, produced through electrolysis of water using renewable energy, with nitrogen from the air using the Haber-Bosch process.

How many people will be working at the plant?

In this phase of the project, it is difficult to provide an exact number of jobs as it will depend on the final design of the factory. It is estimated that 40-50 people will be working on the facility during the operational phase. Our goal is not only to create jobs at the facility but also to contribute to strengthening the local economy. We want to make Sauda and the region more appealing to the new skilled workforce.

Who are the owners of Iverson eFuels AS?

Iverson eFuels is a project led by Hy2gen Norge, Copenhagen Infrastructure Partners (CIP), and Trafigura. Hy2gen is a company specializing in the development, construction, and operation of green hydrogen and green hydrogen derivatives. CIP invests in energy infrastructure and is among the largest fund managers globally in renewable energy. Trafigura is one of the world's leading independent trading companies.

How do you communicate with the local community?

Transparency and open communication are important for us.

Green Café Sessions

At our Green Café, which is an open forum, we update the community on the project's progress. These sessions offer a platform for community members to ask questions and share feedback. We also invite experts to discuss topics related to renewable energy, safety, and sustainability.

Local HUB Coordinator

Gunnar Gauthun, our HUB coordinator, serves as a vital link between the project and the local community. You can find him at Eramet's offices at Birkelandsvegen 1, 4200 Sauda. His door is always open, and he is always ready for a chat over a cup of coffee.

Social Media Updates

Follow our social media channels (Facebook and LinkedIn) for posts about the project's developments, partnerships, events, and milestones. This is a good way to stay connected and informed about our journey.

Local Media Engagement

We invite local media to cover project milestones. Here are our press contact details:

Hege Økland

Managing Director

Email: h.okland@hy2gen.com

Telephone +47 957 53 695

Educational Outreach

We partner with local schools and educational institutions to provide learning opportunities focused on green ammonia, sustainability, and related technologies. We aim to educate and inspire the next generation.

Feedback Channels

We welcome all questions, comments, or concerns. Please feel free to reach out to us via email or the message form on our website's Contact page.

Informative Website: Our website is a reliable source of up-to-date information about the project. We ensure it reflects the latest developments and insights for anyone interested in our progress.

What is the risk of an ammonia factory and what are you doing to mitigate the risk?

- Safety and security for people and the environment is our number one priority.

- Ammonia is a toxic chemical and must be handled with care. An ammonia plant poses specific risks such as leaks, explosion and fire.

- We are working closely with Sauda municipality and other regulatory authorities (the Norwegian Maritime Authority, the Norwegian Environment Agency, the Directorate for Civil Protection and Emergency Planning (DSB), the Norwegian Water Resources and Energy Directorate (NVE), the Norwegian Coastal Administration, the Civil Aviation Authority) to ensure that all the necessary safety procedures are in place.

- The safety zones for the factory and harbor area are being developed and will be presented in detail in the regulatory plan that will be submitted to Sauda municipality.

Will there be any smell from the factory?

There will be no odor coming from the factory during normal operations.

Will there be noise coming from the factory?

The noise from the factory will not exceed the standards set by the Climate and Environment Ministry.

What will happen to the businesses that are currently located at the factory site?

In partnership with Sauda municipality and the businesses impacted by our project, we are dedicated to identifying and assisting in the relocation of these businesses to suitable areas. Our goal is to ensure that their operations can seamlessly continue with minimal disruption.

What are we going to do with the cooling water?

We ensure that no contaminated or heated water is discharged into the river, thereby protecting local marine life from any impact. All cooling water used in our processes will evaporate in the cooling towers, preventing any environmental harm.

How will the Sauda residents be informed in case of Incidents?

The factory will operate with an emergency response plan approved by DSB and Sauda municipality. This plan will include detailed procedures for alerting and necessary measures in case of incidents, to ensure rapid and efficient response.

What is the worst-case scenario?

In the unlikely event of a worst-case scenario, we assume a leak as the most critical incident. We have conducted extensive analyses simulating various types of leaks, their locations, and possible extents. The factory's design includes preventative measures based on these analyses to minimize the likelihood of incidents and their potential consequences.

Will walking and cycling paths around the factory be built?

We are focused on meeting the area's infrastructure needs, like adding walking and cycling paths. We are working with local officials and the community to make sure we offer safe and eco-friendly travel options for our employees and residents.

How will the factory affect the traffic?

Anticipated to produce only minimal additional traffic, our facility's main traffic flow will primarily come from employee commutes, complemented by a modest level of goods transportation, similar to the traffic at Eramet.

Are there any risks of employees being exposed to hazardous materials at work?

We will ensure that our team has the necessary expertise, receives the required training, and is equipped to maintain a safe and good working environment. At Iverson, we adhere to a strict zero-harm policy, and as such, we will implement all necessary safety protocols to guarantee the well-being of our employees.

How will the product be transported?

The green ammonia will be transported in a concealed pipeline through the mountain from Birkeland to a storage facility at Hesthammer, east of Sauda port. Afterward, we plan to load the ammonia from the storage facility onto ammonia tankers aboard ships.

Will the ammonia plant have safety zones around its operations?

- There are spatial restrictions around facilities that produce hazardous substances. Based on the conducted Qualitative Risk Assessment (QRA), we have identified indicative safety zones around the plant and pipeline. These have been assessed against the acceptance criteria described in the DSB's guidelines for major accident facilities. The calculations performed in the QRA at this stage of the project have significant safety margins, but we expect the final safety zones for an approved facility to be substantially smaller.

- Please note that at this stage, the safety zones and the limitations within them have not taken into account mitigating measures that are to be implemented in later project phases that may reduce the extent of these safety zones. We emphasize that the indicated safety zones can be expected to decrease during the course of the project.

- With the development of the facility and its subsequent approval by the DSB, a new and more detailed QRA will be conducted. The risk contours will have a different configuration than what is currently used for the inner, middle, and outer zones.

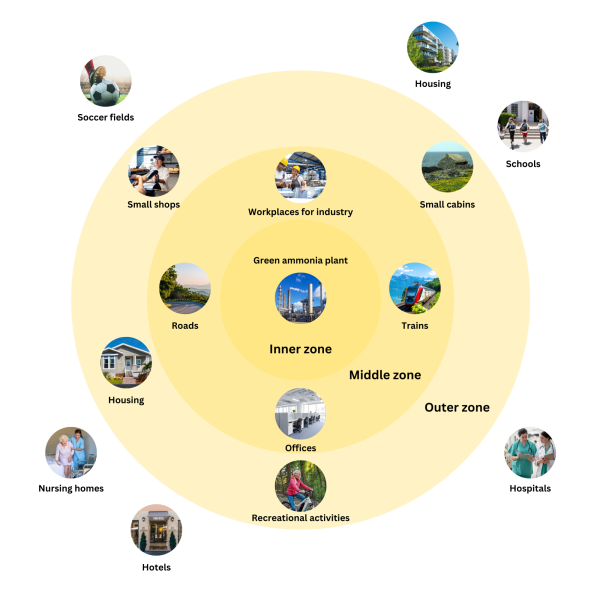

- Here are the DSB's overarching principles for the types of activities allowed in the various risk zones: